VIDEIRA was founded in 1982 and within a few years became a landmark in the Portuguese market for stainless steel hot water tanks.

Having achieved considerable influence over the development of new technology for heating appliances, we have expanded our presence worldwide.

Mission

To design and manufacture high-quality, energy-efficient stainless steel hot water tanks using sustainable processes, meeting the most demanding international standards and exceeding customer expectations worldwide.

Values

At VIDEIRA, we are guided by:

Sustainability – We design and produce with respect for the environment, prioritizing energy efficiency and eco-design.

Integrity – We foster transparency, honesty, and accountability in all relationships.

Excellence – We uphold high quality and compliance standards across all processes.

People-first culture – We invest in our team, nurturing talent and collaboration.

Long-term partnerships – We build trust through shared responsibility and mutual growth.

High Technology and Sustainability

With minimal energy consumption, we are committed to sustainable manufacturing and to the responsible use of our products.

Our Solutions

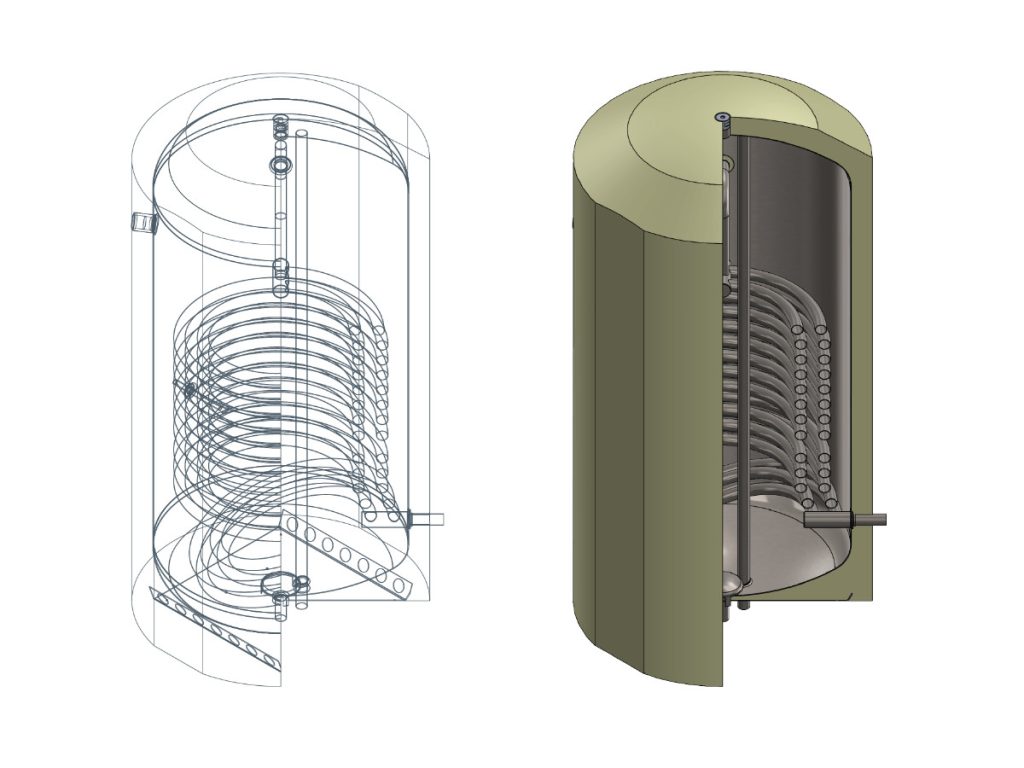

With VIDEIRA you will find a wide range of indirect stainless steel tanks with several designs available.

These solutions are widely recognized for their reliability, comfort, outstanding design, and energy efficiency.

We work hard every day to meet the highest expectations. VIDEIRA provides excellence that goes far beyond what we see in the finished product.

Our track record of fine in-house engineering with rigorous internal testing and multiple external certification processes are what provides our customers complete confidence in our services.

Our Processes

VIDEIRA has equipped its production facilitieswith vital resources such as advanced technology, modern facilities – including a completely new R&D department and laboratory with state-ofthe-art technology and high-quality materials.

With an ecofriendly mindset. VIDEIRA is also certified to ISO 9001, which allows manufacturing processes to comply with the highest quality and safety standards.

Export

Our production capacity, quality standards, and flexibility make us a reliable partner for distributors, OEMs, and professionals across the globe.

Our Evolution

1980

Company founded in Recarei - Paredes.

1983

Big size water heaters range.

1989

First Portuguese manufacturer to use PU injected as thermal isolation.

1990

New range Multi F Water Heaters

1993

Relocation for new building (1800 m2).

1994

First Portuguese manufacturer with certified Water Heaters.

1999

International Market.

2000

Early tests with Stainless Steel Robot construction of the thermodynamics lab launch of the DUPLEX range.

2008

Introduction of tanks with low temperature heat sources.

2009

Release stainless steel AISI 316L range in domestic market.

2010

Beginning of the production with AISI 444.

2014

Start of in-flow foam and finishing line.

Installation of hydraulic press for in-house bottoms production.

New lab tests to R&D and ErP tests.

2015

Introduction of the new 'Tank on Tank' model.

2016

Beginning of export to North America.

2019

New pickling plant.

2020

Formal partnership between Videira and Joule Group.

2022

Relocation of industrial warehouse production to a new building.

2023

New production site dedicated to high volumes.

2024

Opening of a second production building in Lordelo, with 10,000m2 dedicated to large volumes.